Have you written your GCE? If yes, then you must be looking forward to seeing your GCE result. Now this is where the GCE result checker comes in. Before we proceed to what the GCE result checker is all about, let’s first take a look at what GCE is all about.

GCE (General Certificate Education) also called A ‘level is an entry qualification for universities in Nigerian and many other locations around the world. It is referred to as a British academic diploma that is recognized internationally.

And is also valid for a very long time and taken as evidence of academic ability to be admitted into universities, colleges, and so many other academic institutions. GCE comprises different subjects that cover an entire spectrum of specializations and branches a student chooses to follow depending on their level of education.

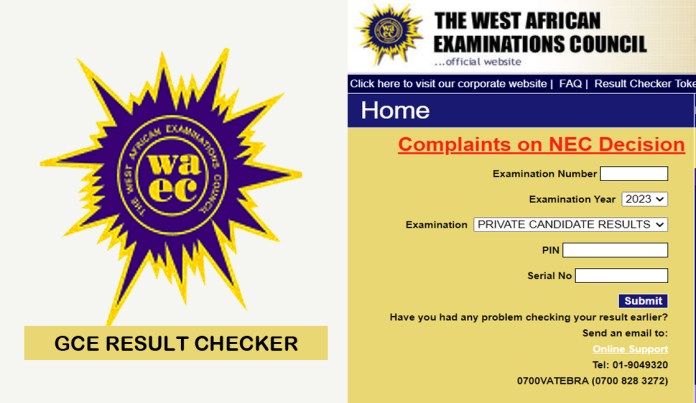

The GCE result checker is a medium or a page that candidates can visit to access their GCE results anytime they want. Provided it has been released. The GCE result checker is however similar to the WAEC result checker. That is because GCE is an exam conducted by WAEC.

So, if you want to check your GCE result, you’ll have to make use of WAEC’s result checker online. However, if you are finding it difficult to use the GCE result checker to check your results online.

Fret not as this article is here to provide you with an easy guide to using the online checker to access your results after they must have dropped. So, without further ado, let’s explore!

Requirements To Use GCE Results Checker

To use the checker, there are certain requirements you must meet. That is, there is certain information the site requires you to provide. That includes;

- Your Exam Number and Exam Year.

- Your Pin.

- Serial Number.

With these, you can check your results online. However, keep in mind that you need an internet-connected device to be able to access the page. Once you have all that, you can now follow the steps below to check your result online.

How To Use the GCE Result Checker

Using the result checker to access your GCE results online is not a big deal. And it is also very easy to do. Provided you have all the required information available. That includes; your examination number, year, pin, and serial number. With that information available, you can now follow the steps below to check your GCE result;

- Visit WAEC’s official website @ https://www.waecdirect.org/.

- Provide your examination number.

- Enter your exam year.

- Then at the examination section, select “Private Candidate Result”.

- Then enter your pin and your serial number.

- After that click on “submit”.

Then your results would be displayed before you. You can now see how well you’ve done and access all your grades on the platform.

FAQs

How Can I Get My GCE Pin?

To be able to check your GCE result, you would have to buy a GCE pin online or in a physical store where it is being sold. But if you’ve already been given one, you do not have to buy one. Except if you have exhausted it.

So, if you want to get the PIN that lets you access your GCE result, you can buy online on a legit site. Or visit a café that sells to get a scratch card. Then follow the above-listed steps to sign in and access your results online.

Is GCE Result 2023 Out?

As of now, the GCE result for 2023 is not yet out. But if you have written the exam maybe in previous years, you can access your result using the GCE Result Checker platform.

For 2023 candidates, you will be able to access your result when it is out. So, once it drops, you can follow the above-listed steps to access it.

Is GCE Registration 2023 Still On?

Currently, the GCE registration form 2023 second series is still on. As it is said to commence on the 13th of July and end on the 14th of August. So, while this is still on, you can go ahead and register, providing all the required documents to be able to write your exams. Success!